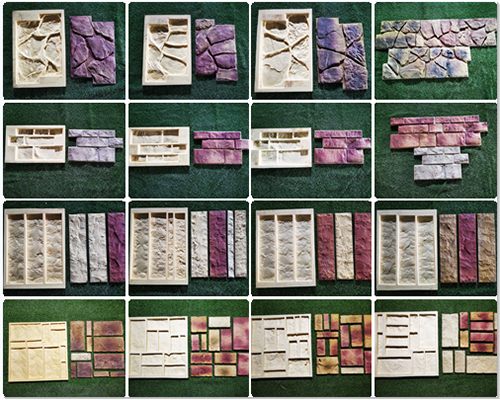

Top Quality Concrete Artificial Stone Silicone Molds

Enquiry Email: harvey_lya@zzlya.com

Product Description Artificial stone silicone mold is the main product of our factory. Due to the particularity of the production materials of artificial stone, which is required to have……

Introduction

Product Description

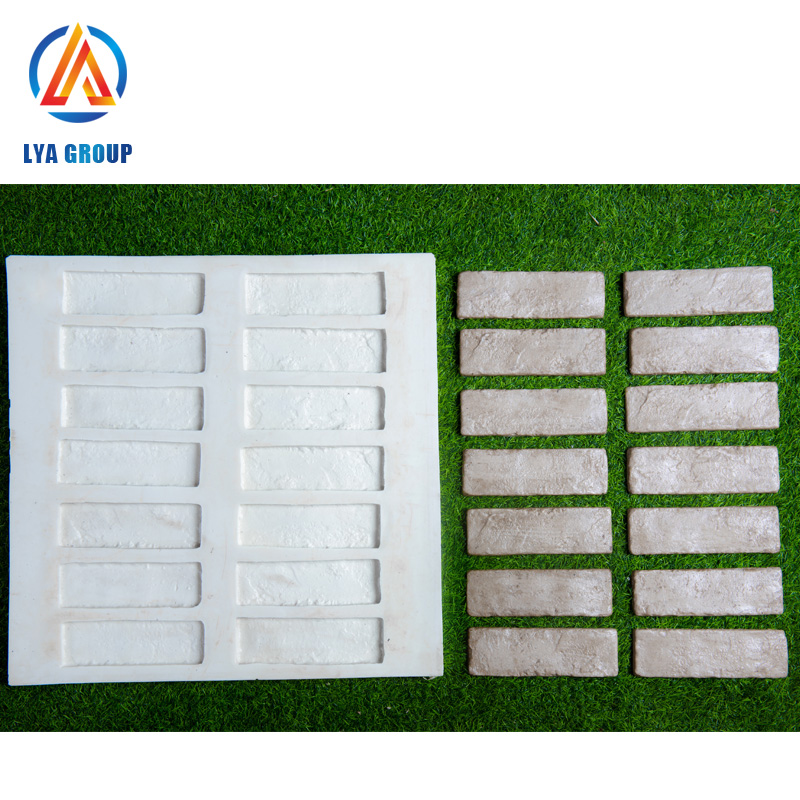

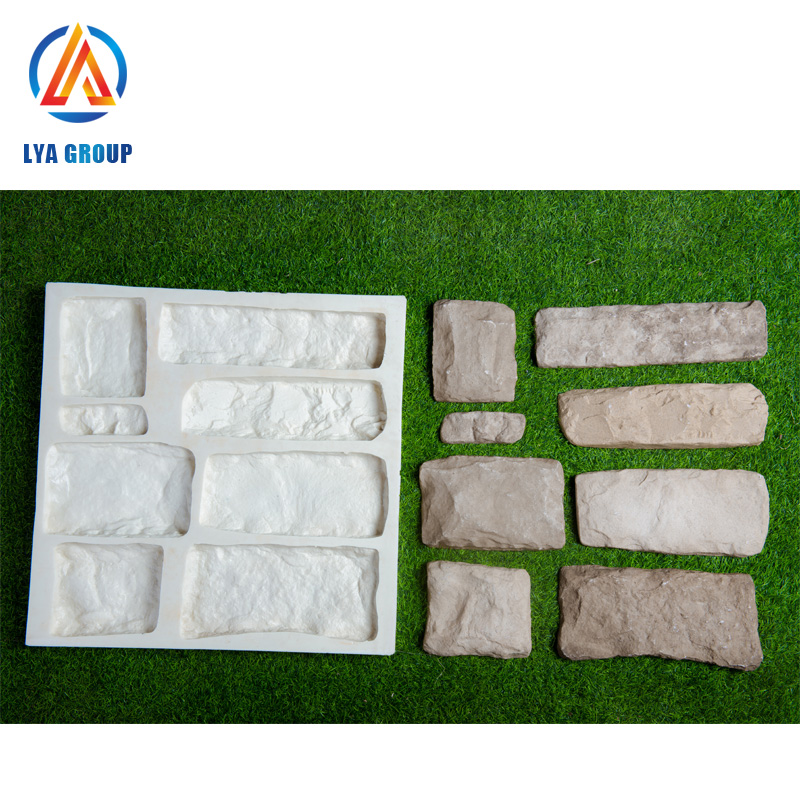

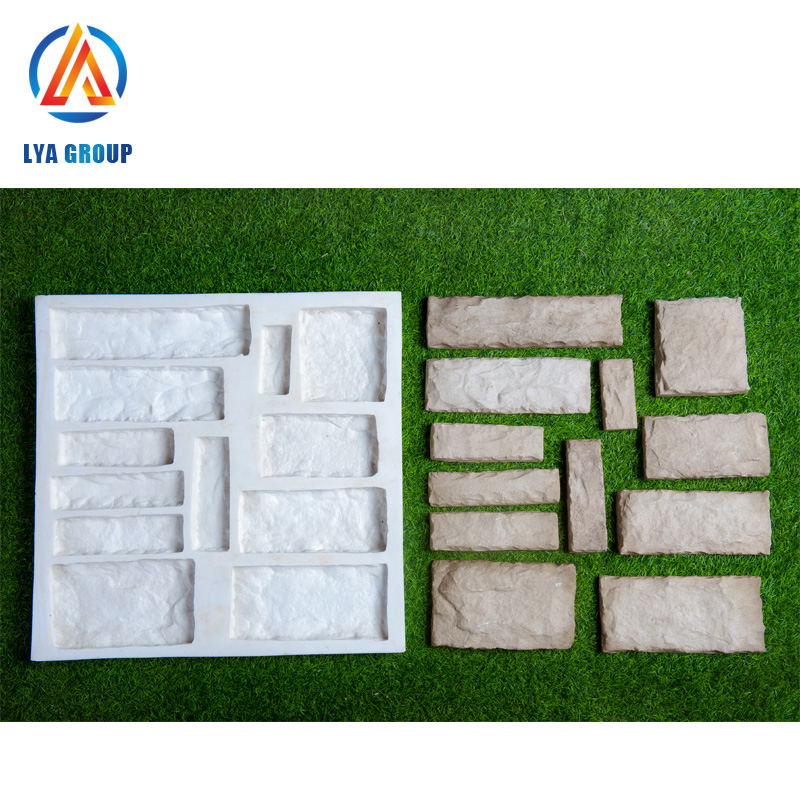

Artificial stone silicone mold is the main product of our factory. Due to the particularity of the production materials of artificial stone, which is required to have different heat resistance, expansion resistance, hardness, acid and alkali resistance and tear resistance than general resin mold silicone rubber, so in order to adapt to the special requirements of artificial stone molds suggest that they must not be mixed.

Artificial stone silicone mold features:

1. Various designs and beautiful surface textures are molded directly from the original stone samples. The textures and colors are natural and the colors are unified;

2. Good wear resistance;

3. High strength and zero drying shrinkage; low drying shrinkage (less than 0.5mm/m), no cracking;

4. Good freeze-thaw resistance, the compressive strength is still as high as 10.7Mpa after 15 freeze-thaw cycles at -20°C, fully able to cope with various complex outdoor environments in the north and south;

5. Low water absorption, can be directly used for exterior walls;

6. No radioactive substances, environmental protection and no radiation.

| Name | Rubber Artificial Stone Molds |

| Size | 560*560*40mm |

| Lifetime | 2000times |

| Material | Silicone Rubber |

| Weight | 7kg/piece |

| MOQ | 10pcs/pattern |

Related Products

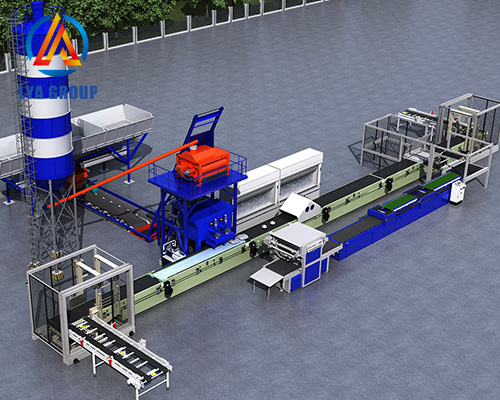

Concrete dosing machine system, also known as a concrete batching system or concrete dosing plant, is a specialized equipment used in concrete production to accurately measure and dispense the various components of a concrete mix. It ensures the precise proportions of cement, aggregates (such as sand and gravel), water, and additives are achieved for consistent and high-quality concrete production.