artificial stone silicone mould for cultured stone veneer molds

Enquiry Email: harvey_lya@zzlya.com

Product Description Artificial Stone Molds Artificial culture stone is made of pumice, ceramsite, calcium silicate and other materials through professional processing. Then we cut and chise……

Introduction

Product Description

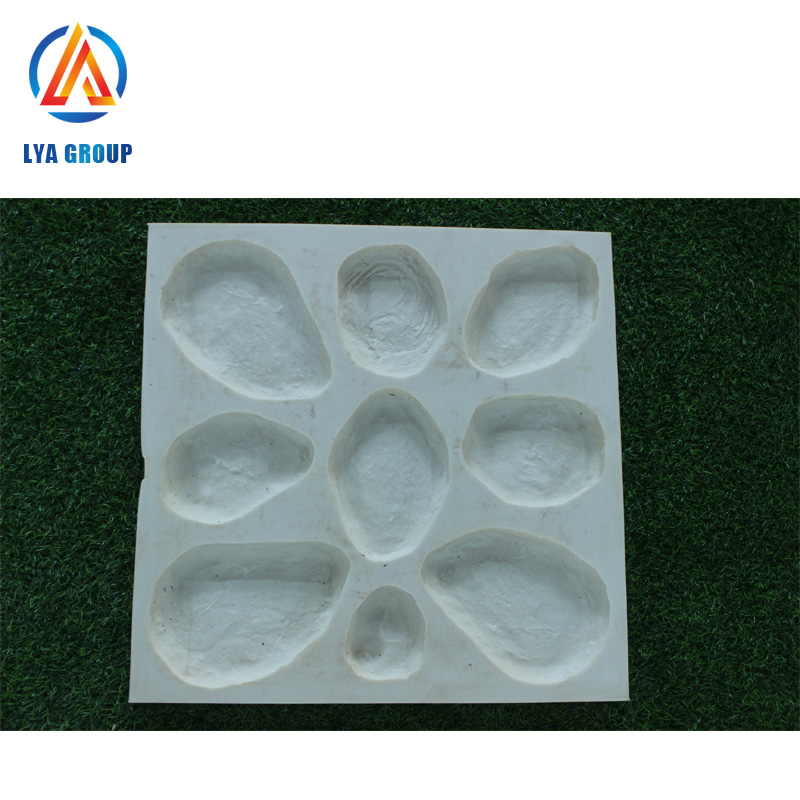

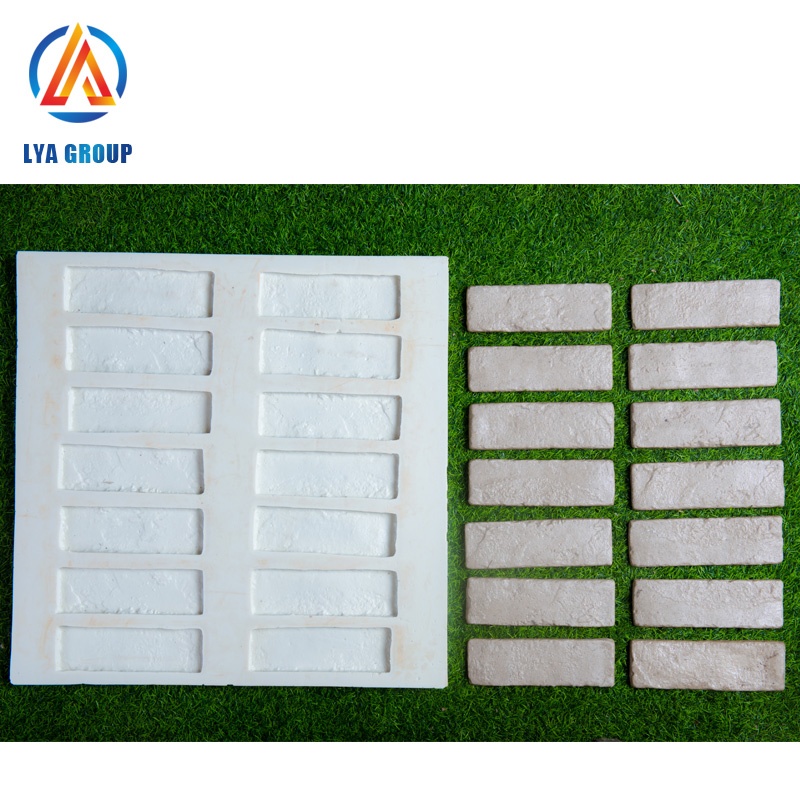

Artificial Stone Molds

Artificial culture stone is made of pumice, ceramsite, calcium silicate and other materials through professional processing. Then we cut and chisel natural stones until they fit our concrete stone facing mold. High grade artificial culture stone has the characteristics of environmental protection, energy saving, light texture, rich color, no mildew, no burning, good frost resistance, easy installation and so on.

1. High quality, natural color and delicate texture, solid surface.

2. Light weight, only 1/2 or 1/3 the weight of natural stone

3. Hundreds of colors can be customized.

4. Installation is quicker, easier and cheaper

5. Virtually maintenance free

6. Energy saving comparing to the natural stone.

7. Environmental friendly, odor-free,radiation-free,non-toxic,heat-insulation,non-radioactive.

8. Durable and unlikely to rust, piebald or fade. Resistance to fracture and impact. Fire retardant. Sound insulation, dampness penetration.

Specification:

| Product Name | Artificial stone mold |

| Szie | Standard szie 560*560*45mm, Irregular size, supporting customization |

| Type | Heat resistance,No deforming |

| Delivery time | Within 15 days, depending on the quantity |

| Material | Silicone rubber |

| Thickness | 20~40 mm / 45±20 mm / 20~60 mm,supporting customization |

Advantages:

1. Customizing design with original sample or 3D drawings provided

2. Imported modified silica gel, more durable

3. High tear strength, more times of filming, up to 3000 times

4. High temperature resistance, acid and alkali resistance, no expansion, no deformation, easy coloring

5. Mould material can be recycled and refurbished

Our Services:

Teach production technology for free, provide pigment matching scheme, guide production equipment debugging, push mold style, customize mold for free, get picture album for free

After you recieve molds, we provide the technical support for assist you in producing beautiful and strong artificial stone

Making Process:

1. When installing, the horizontal lines and flatness of the wall should be measured, and a horizontal line should be played every 50cm

2. Before installation, be sure to lay 2-3 boxes cultural bricks and cultural stone on the flat ground, and arrange the best effect after installing the wall.

3. When installing, first attach the corner, then stick the plane, after the adhesive is full, press the adhesive to squeeze around the cultural brick to avoid the empty brick of cultural brick during installation.

4. Cut and adjust the cultural brick according to the construction needs.